Dashboard Tooling Mold Instrument Cluster Mold Automotive Mold

1.Product Introduction

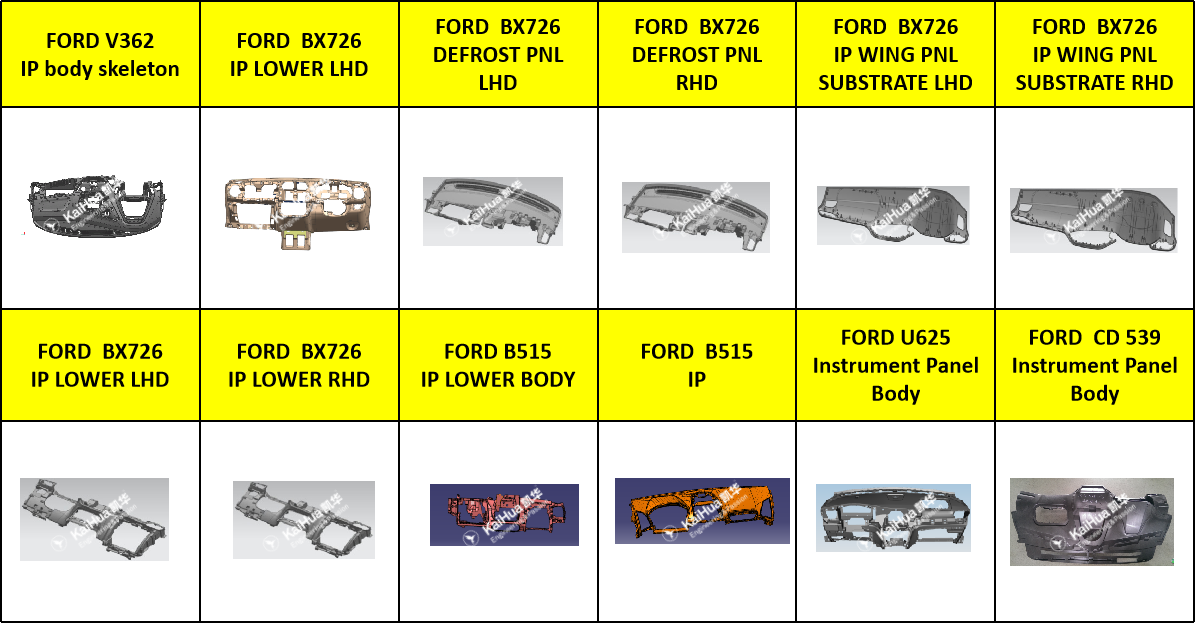

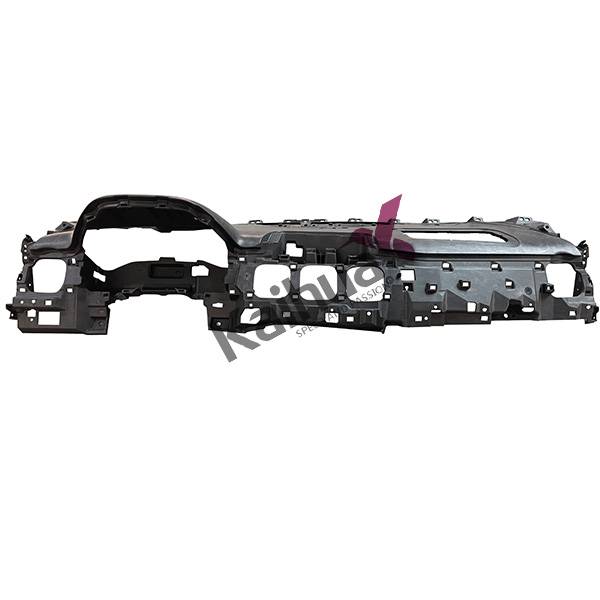

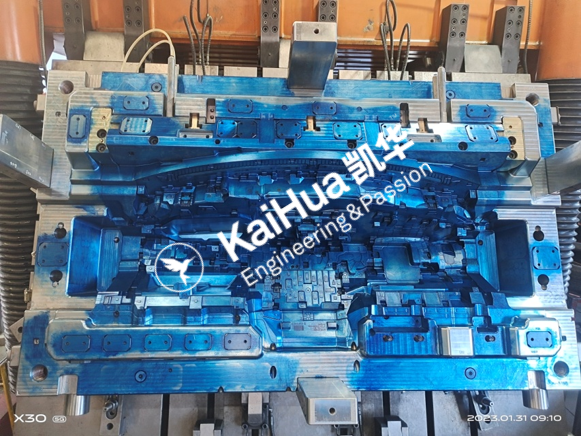

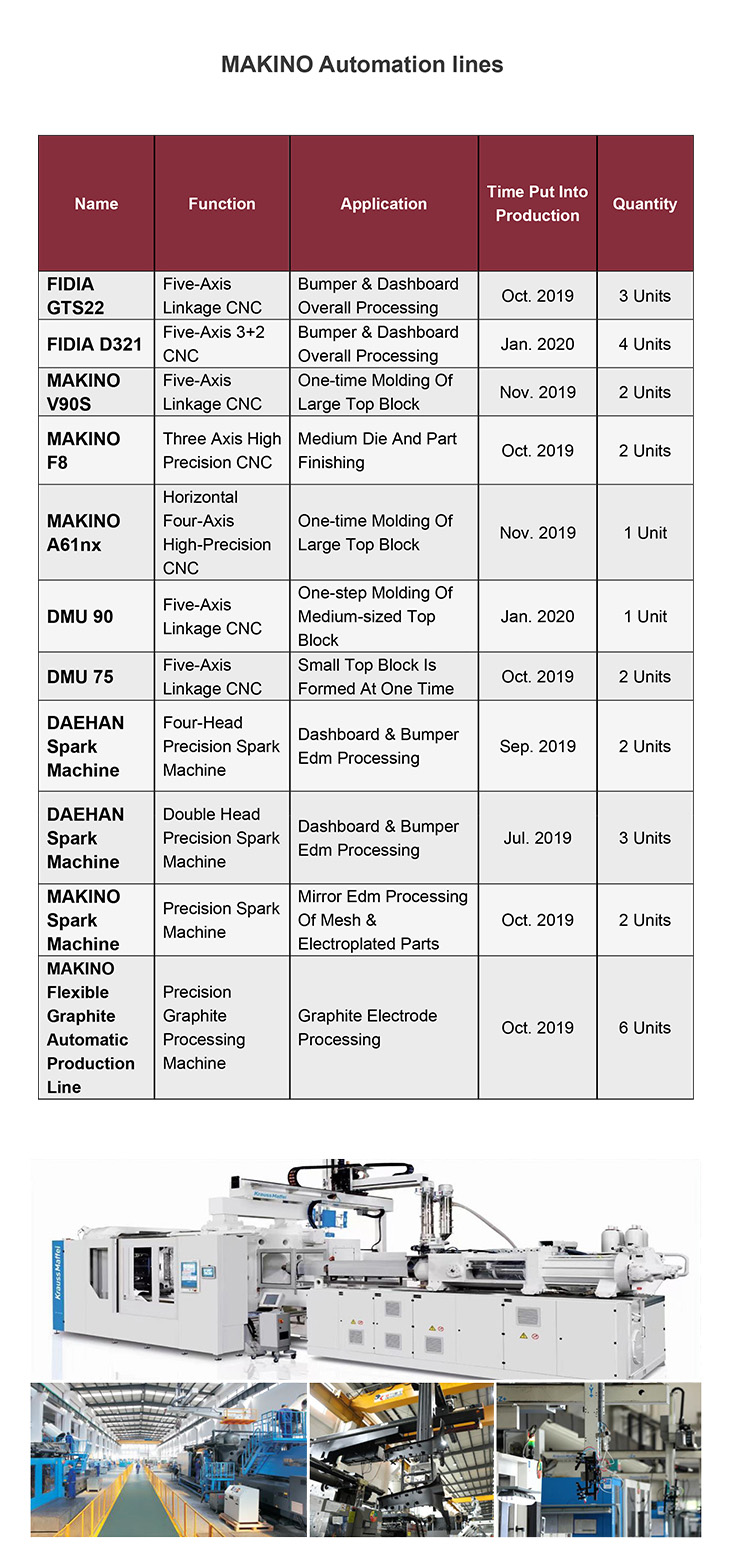

As a top automotive mold manufacturer and trusted automotive mold maker, Kaihua makes high-quality Dashboard Injection Molds for the global car dashboard market. We use top-notch steels: 1.2738, 718H, P20, NAK80, S136, H13, etc.. Brands include Germany's Buderus, Lurgi, and Böhler. With 20+ years of experience, our molds (used by BMW, VW, BYD) have an industry-leading 0.001mm precision—thanks to Makino 5-axis machines. We're good at thin wall injection molding, making 2.0mm ultra-thin dashboard parts and cutting weight by 15% with our Mucell tech (great for EV range or ICE fuel efficiency).

Our automotive molds use these premium steels, lasting 500,000+ cycles. They work smoothly with china automatic molding machine brands like KraussMaffei and Haitian, getting standard dashboards done in 65 seconds. Every mold has ISO 9001:2015 certification and strict pre-ship tests ( CMM checks) for quality.

In addition, two of Kaihua's prominent Automobile Plastic Injection Molds—the Through-type Rear Lamp 2-Color 2-Position Mould and the Automotive Taillamp 3-Color 3-Position Mould—have received wide praise in the industry.

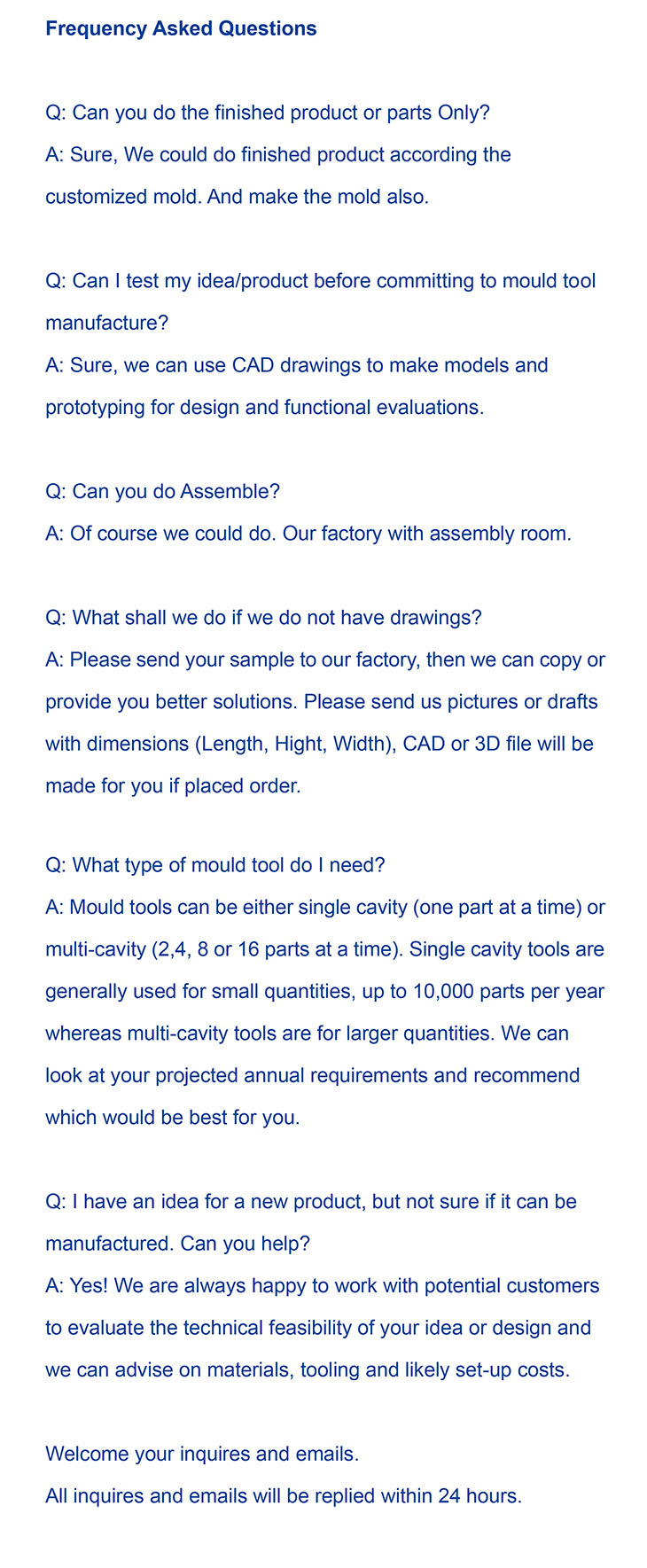

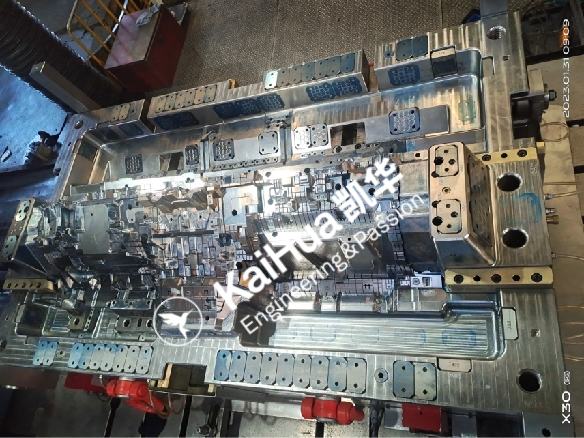

2. Product Display

|

Product Name |

Dashboard Upper body |

|

Plastic Material |

TPE |

|

Injection Molding Machine Tonnage |

2800T |

|

Number of Mold Cavities |

1 |

|

Mold Material |

1.2738 Buderus/P20 Fink/2738H/Customized |

|

Grain or Electroplate |

Grain |

|

Automatic Demolding Requirements |

Robot |

|

Hot Runner Brand |

HTS |

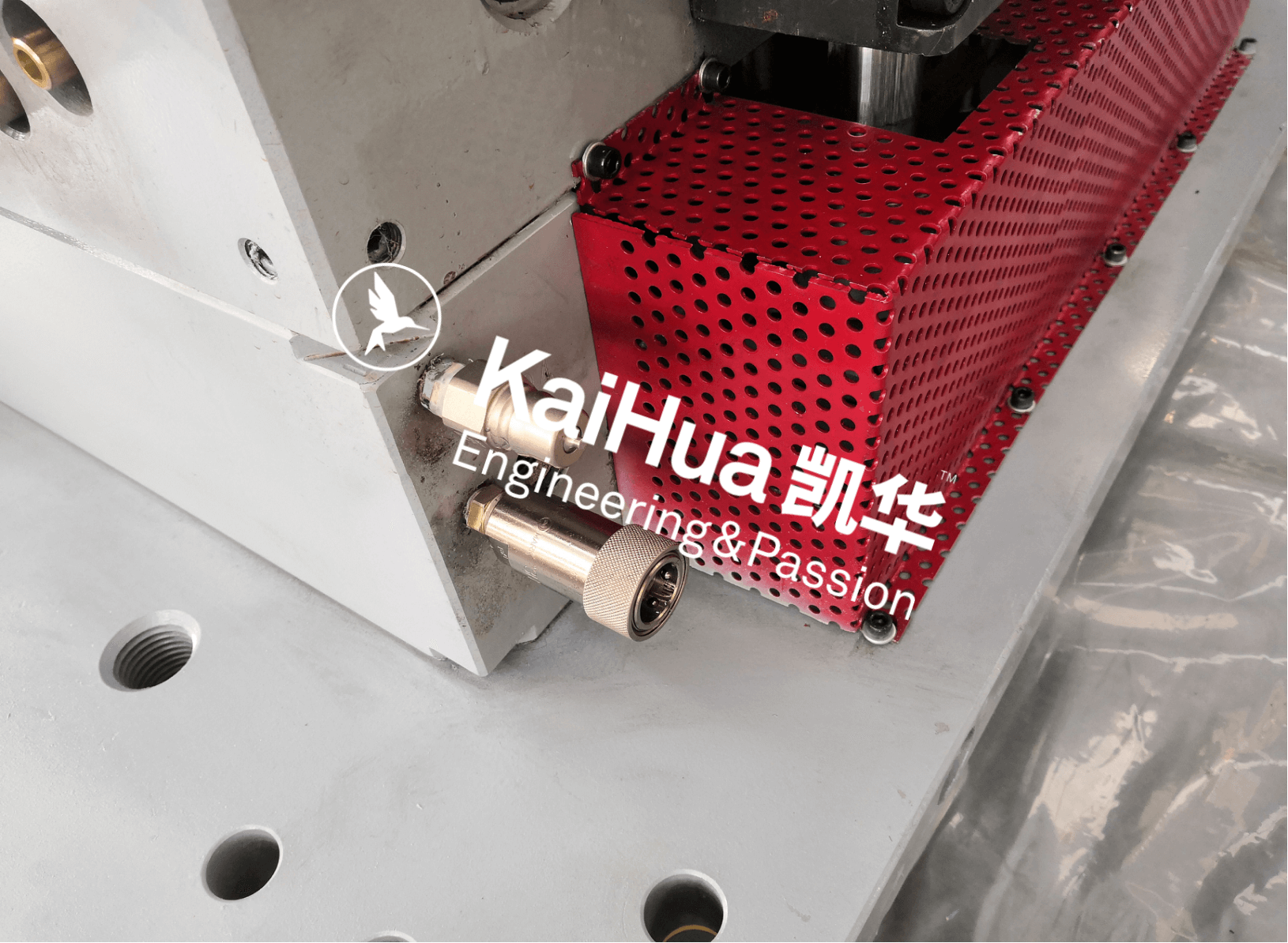

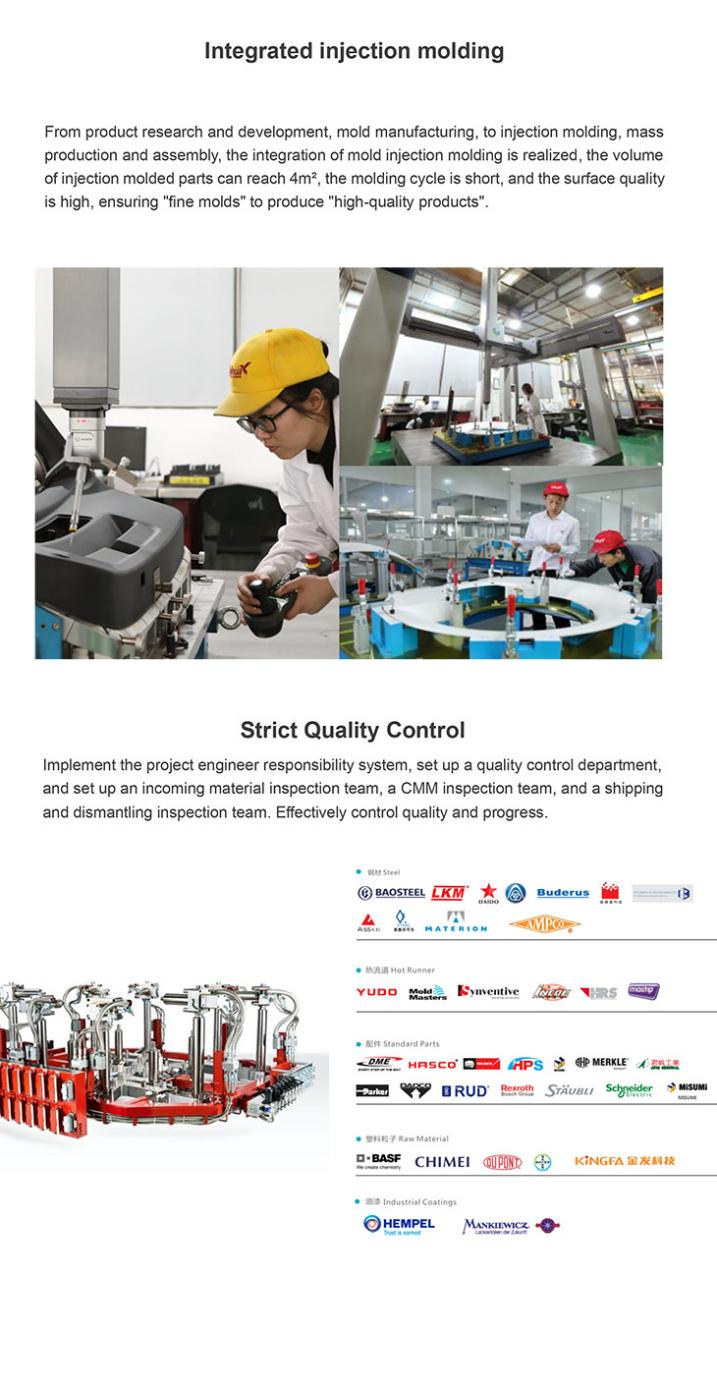

3.Production details

4. Product feature and application

(1) Product feature

l Kaihua's dashboard injection molds, a top choice for the global car dashboard market , stand out with precision and efficiency that meet the needs of leading automotive mold manufacturers and automakers. Powered by advanced 5-axis Makino machining centers—key for high-end automotive molds —they achieve an industry-leading 0.001mm tolerance, ensuring seamless fits for critical components like air vents, airbag slots, and touchscreen recesses.

l Our expertise in thin wall injection molding enables 2.0mm ultra-thin dashboard parts, while proprietary Mucell technology cuts part weight by 15%—a game-changer for boosting EV battery range or ICE vehicle fuel efficiency. With modular design, we reduce mold development time by 20% vs. industry averages, and each mold boasts a 500,000+ cycle lifespan, pairing perfectly with china automatic molding machine brands (KraussMaffei, Haitian) for 65-second cycle times.

l ISO 9001-certified, every mold undergoes strict testing (3,000 dry cycles, CMM checks) to guarantee quality. As a trusted automotive mold maker , our team offers timely support to keep your production on track, making these molds ideal for automakers aiming to excel in the competitive car dashboard market .

(2) Product application

- Trusted by global automakers including Great Wall, BAIC, BYD, and premium brands like Mercedes-Benz, our dashboard molds excel in both ICE and EV models—supporting 10,000+ monthly outputs with seamless integration of air vents, screens, and safety features.

- Backed by a 200-strong design team (with 15 mold flow experts, 1 silver-certified), we resolve complex challenges: optimizing deep-recess structures for European clients, cutting rework from 18% to 2% via advanced simulations.

- Compatible with top china automatic molding machine brands (KraussMaffei, Haitian), our molds achieve 65-second cycles while ensuring 500,000+ lifespan—170% longer than standard molds, slashing long-term costs.

- Global support network (NA, Europe, Asia hubs) delivers pre-launch design tweaks and rapid post-delivery fixes (e.g., 8-hour turnaround for Thai clients), keeping production on track.

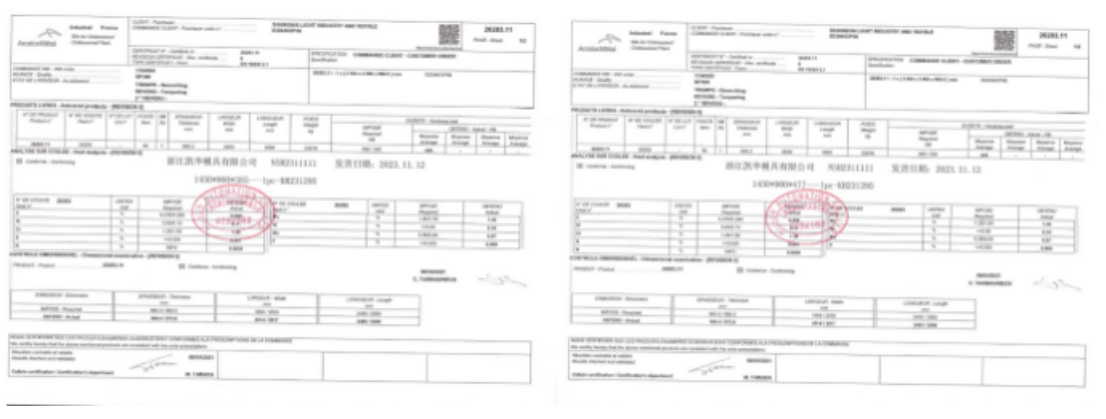

5.Product qualification

(1)Dashboard Injection Mold Trial Process

Kaihua's custom plastic injection moulds are purpose-built for automotive applications, with a focus on manufacturing vehicle air grilles. Engineered for high-volume production, these moulds guarantee consistent quality and precision across every unit—making them an ideal choice for manufacturers aiming to produce air grilles that balance durability, visual appeal, and functional efficiency, suitable for a wide range of vehicle models.

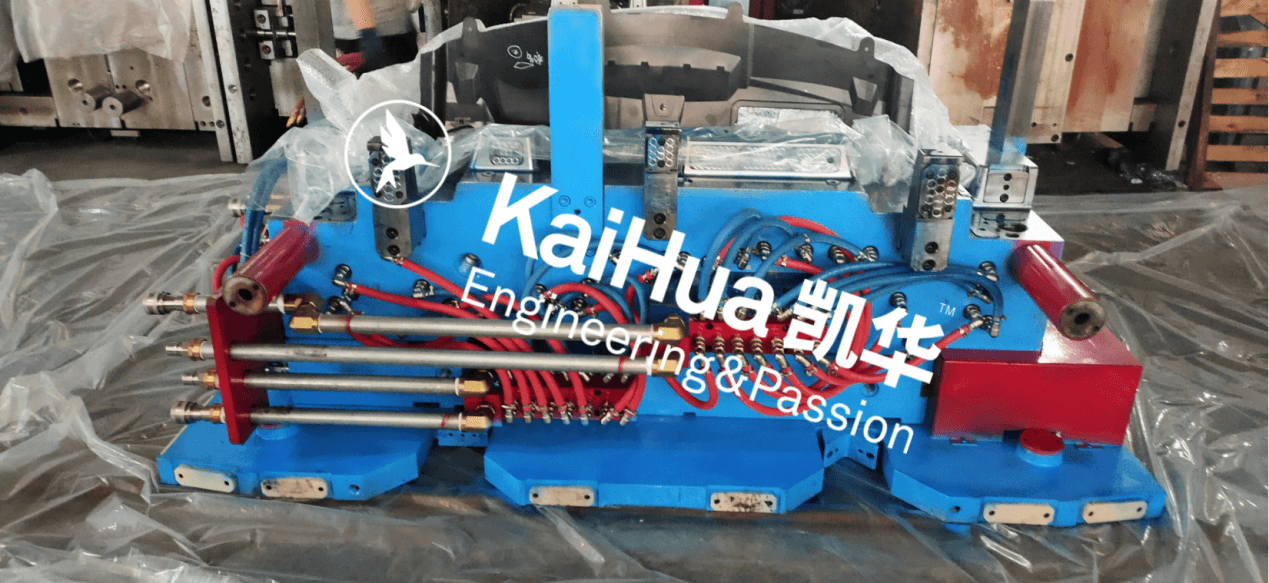

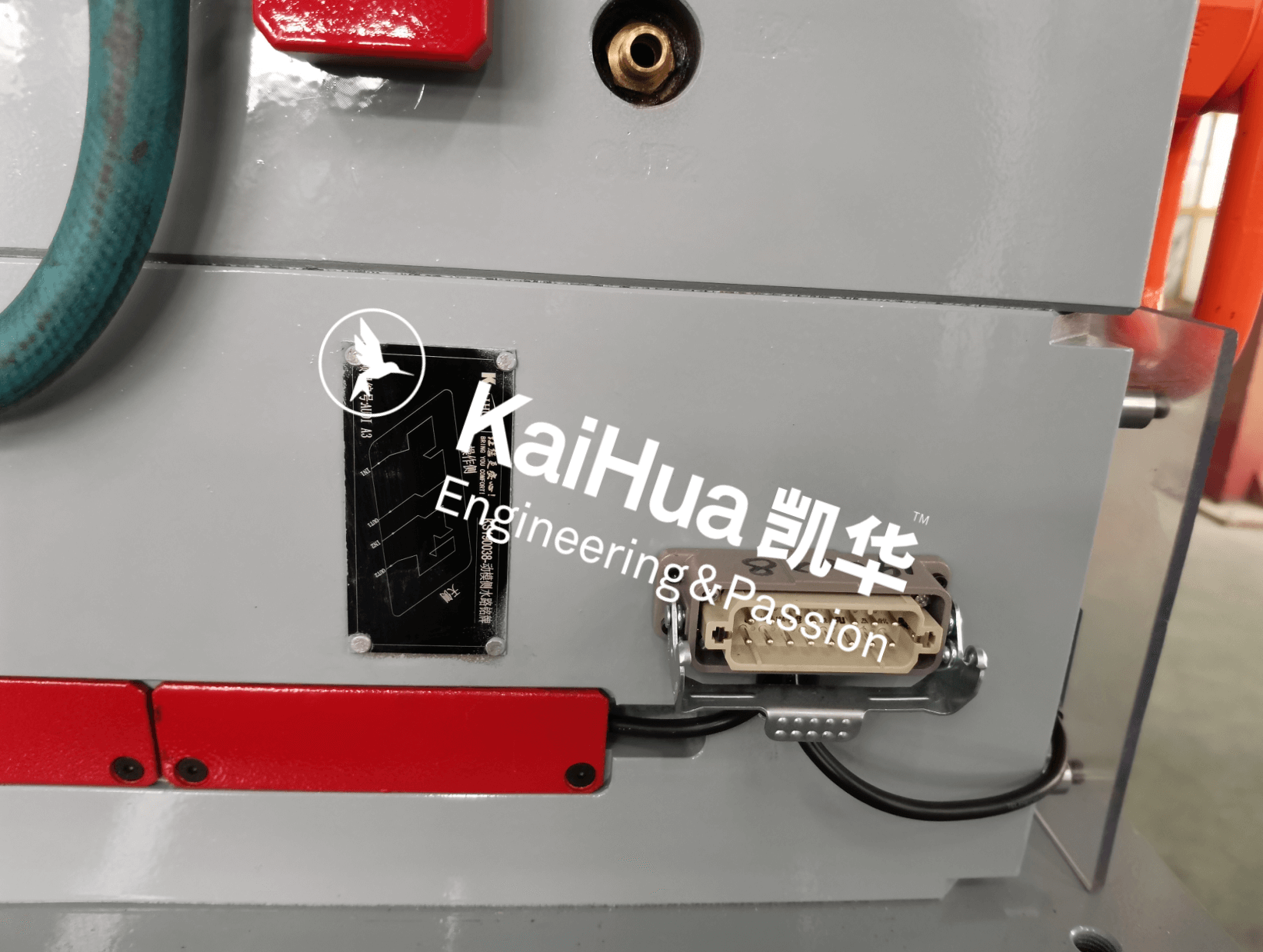

(2)Product shipment and packaging photos

(4)Design review photos

(5)Photos of the Technical Department Meeting

(6)Certificate

To learn more about Kaihua's certificates, please click here

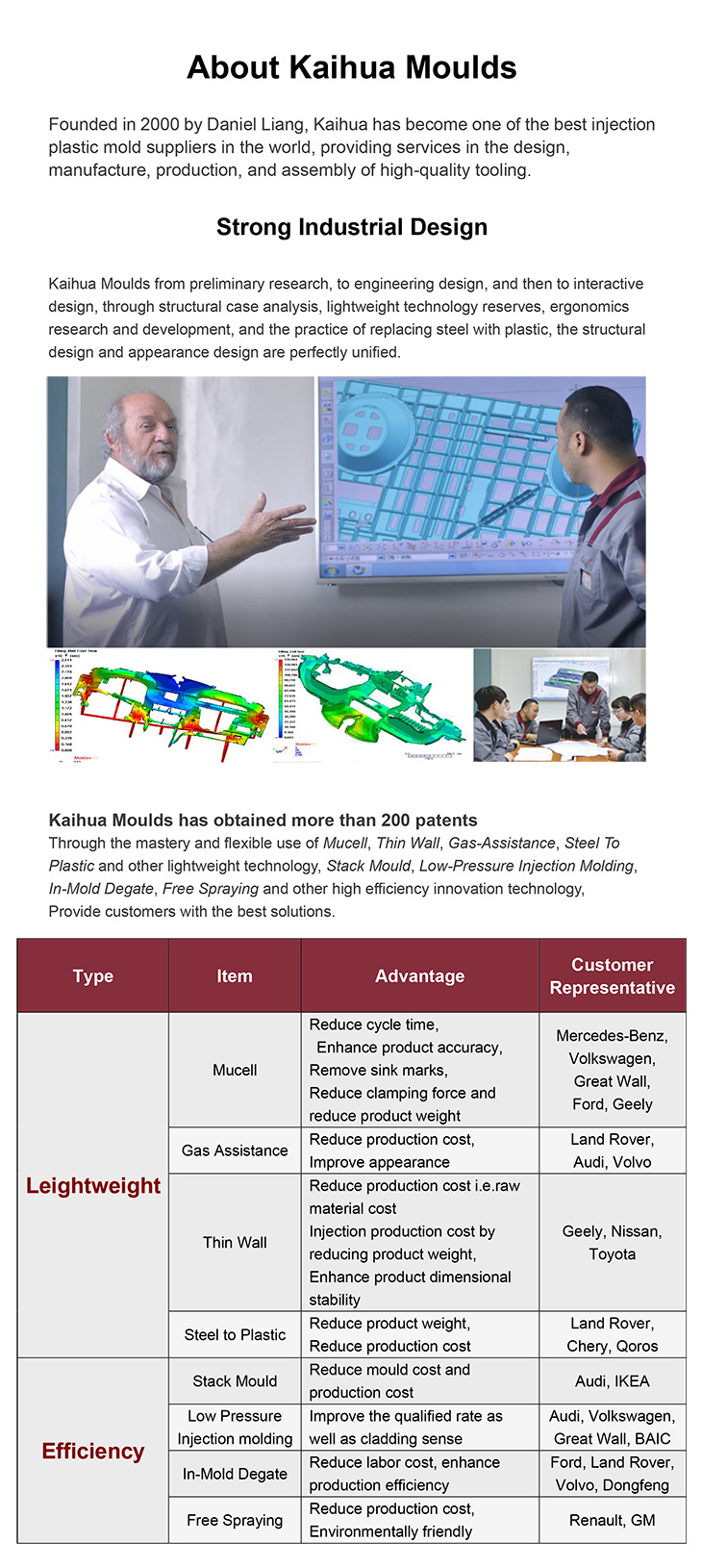

7.Kaihua Mould Advantage

8.FAQ